Anderson-Cook’s Marand Model 300V Series Vertical

By early 2000 a new manufacturing philosophy required the creation of a new machine. We gave our engineers a clean sheet of paper and a goal: maintain Anderson-Cook quality while designing, from scratch, a machine whose footprint and functionality were dedicated to the cell concept. The result was the Model 300V, a fundamentally different machine. Twin servo-motors, each with their own roller-screw, replaced mechanical synchronization with highly precise, easily adjustable, electronic synchronization. Elimination of the hydraulic unit freed up floor space. Rotating this independent-axis concept into the “vertical” reduced the machine’s foot print and reduced required factory floor space. Additionally, all operational and maintenance points of access were moved to the machine’s front or back. Multiple 300V’s can stand in close approximation—a third means of saving floor space.

By early 2000 a new manufacturing philosophy required the creation of a new machine. We gave our engineers a clean sheet of paper and a goal: maintain Anderson-Cook quality while designing, from scratch, a machine whose footprint and functionality were dedicated to the cell concept. The result was the Model 300V, a fundamentally different machine. Twin servo-motors, each with their own roller-screw, replaced mechanical synchronization with highly precise, easily adjustable, electronic synchronization. Elimination of the hydraulic unit freed up floor space. Rotating this independent-axis concept into the “vertical” reduced the machine’s foot print and reduced required factory floor space. Additionally, all operational and maintenance points of access were moved to the machine’s front or back. Multiple 300V’s can stand in close approximation—a third means of saving floor space.

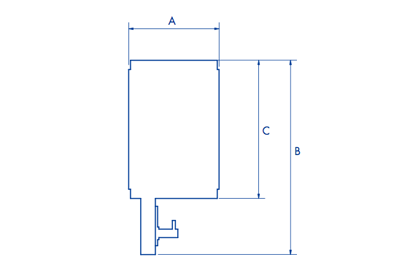

The model 300V is available in configurations of 330V, 340V, and 350V accommodating rack/tooling lengths of 24″, 36″, 48″, respectively. (See table below for more details). Further customization is available for automatic parts loading, multiple rack/tool configurations, and quick-change fixtures. On a micro level the high speed, independent servo-motors allow for fast, finite adjustments. On a macro level the independent axes design allows both tools to be quickly located at one end of the machine for service and tool change. The 300V line accepts a variety of electrical power inputs, sports a self-contained oil or water based coolant system, and is constructed of rigid welded steel.

Choosing a Machine

Machine choices usually “start with the part”. The part’s characteristics will typically determine the size machine needed. Our engineers can quickly and accurately assess your part’s requirements, guiding you to a machine ideal for your needs while avoiding the cost-overages of “too much machine.” One more way Anderson-Cook experience saves you money.

| Model 330V | Model 340V | Model 350V | |

|---|---|---|---|

| Height | 120″ | 150″ | 175″ |

| Width (A) | 57″ | 57″ | 57″ |

| Depth (B) | 129″ | 129″ | 129″ |

| Depth with Overarm (C) | 90″ | 90″ | 90″ |

| Motor Size* | 30HP | 30HP | 50HP |

| Weight | 20000 | 25000 | 30000 |

| Maximum Rack Size | 24″ | 36″ | 48″ |

| Fixture Width* | 3.63″ | 3.63″ | 4.75″ |

| Standard Daylight Opening* | 5.5″ | 5.5″ | 6.0″ |

| Max. Stroke of Slide | 30″ | 44″ | 56″ |

| Max OD of Work Part* | 2.0″ | 2.0″ | 2.5″ |

*Can be customized to suit the desired application