Products

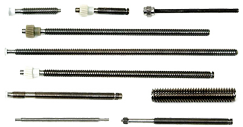

Lead Screws & Spindles

High speed cold drawing equipment with straightening to meet the strictest runout requirements while reducing material costs.

- Precision in-feed and thru-feed rolling of lead screws and spindles on automated rolling machines.

- High speed CNC controlled machining, both multi-spindle and single spindle for finished machining.

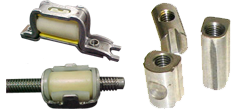

Drive Block Assy & Drive Nuts

- Stamped / In Die Tap & Thread Drive Block Assembly with Plastic Molded Insert.

- High speed, automated tapping of internal thread forms.

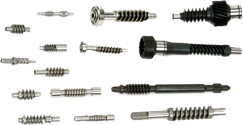

Worms & Threads

- Cold formed or screw machined blanks for producing high quality finished worms and threaded parts.

- Precision in-feed and thru-feed rolling of worms and threads with auto-loading.

- Special designed high-speed, dual spindle milling machines to assure tight tooth tolerances and near perfect PD runout.

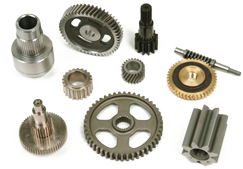

Gears

- Hobbed gears, both spur and helical from 5.0 module (5DP) to 0.4 module (64DP) on state of the art, 5-axis, auto-loaded hobbing machines.

- Shaper cut gears, both spur and helical from 5.0 module (5DP) to 0.4 module (64DP).

Input / Output and Armature Shafts

- SAE1050, 1053, 1144, 8620.

- O.D.:15mm - 75mm

- Length: 100mm - 500mm

- Spline: Internal/External Involute

- * Typical Class 5

- Diameters: +/- 0.005mm

- Lengths: +/- 0.025 mm

- Surface Finish: 0.2 Ra

Materials:

Characteristics:

Tolerances: